In periods in which the contribution margins are gradually being reduced to multiple causes and energy costs are recognized as important drivers of business competitiveness (think for example to process manufacturers with the cost of energy impact on the cost of goods sold amounted to 30-40 %) is necessary to identify the most appropriate methodology and effective way to achieve energy efficiency goals and to measure the resulting business performance; In this context, monitoring systems play a key role, allowing you to check the areas of greatest potential benefit to upgrading the efficiency and rationalization, the correct integration of generation plants (conventional and renewable) with respect to users, the dynamics of consumption by department / line loss management.

What is a monitoring system?

An energy monitoring system is a set of tools for real-time measurement of energy consumption of significant machinery, plant or equipment.

What opportunities can give it?

The use of a monitoring system allows to obtain a complete and integrated vision of energy consumption, not achievable through a simple analysis of the bills.

With specific tools and tech you can collect real-time all the variables significant energy, and then transfer, analyze and tween them with the use of dedicated hardware and software.

The main advantages of installing an energy monitoring system are many:

- Analysis of the parameters and energy consumption, to optimize the operation of the system and to determine the actions to be taken;

- Parameter view, both in real-time is related to variables specific time (eg. Currents, voltages, power, power factor);

- Real-time alerts on energy consumption in case of exceeding of thresholds or parameters are customizable;

- Timely management of losses’ resolution (eg. water, compressed air, etc. …);

- Identification and study of the efficiency measures are feasible and what-if analysis;

- Filing and recording data with the set frequency;

- Compare multi-site consumption, relate to similar plants in different factories.

From what is made up of a monitoring system?

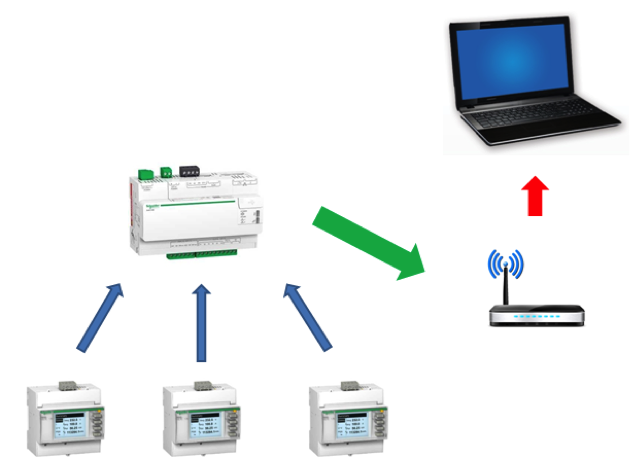

A monitoring system is composed of a series of gauges, variable depending on the type or types of the parameters to be monitored, and by a hardware with the task of storing, recording, and transferring data to a cloud platform or inside company’s server.

The data measured (electrical, thermal, pneumatic or more depending on your needs) are sent to a platform that allows you to develop and implement the data depending on the area you want to look into. Through the elaboration of specific graphs and spreadsheets is possible to obtain detailed the significant parameters from the analysis of which it is possible to identify energy efficiency measures to be implemented.

The team of Idra is available to support you in all the activities related with the energy monitoring from technical support during the study of the most suitable system, installation of components and related testing with customization of the platform for data analysis, drawing up final report containing efficiency measures specific to your company.